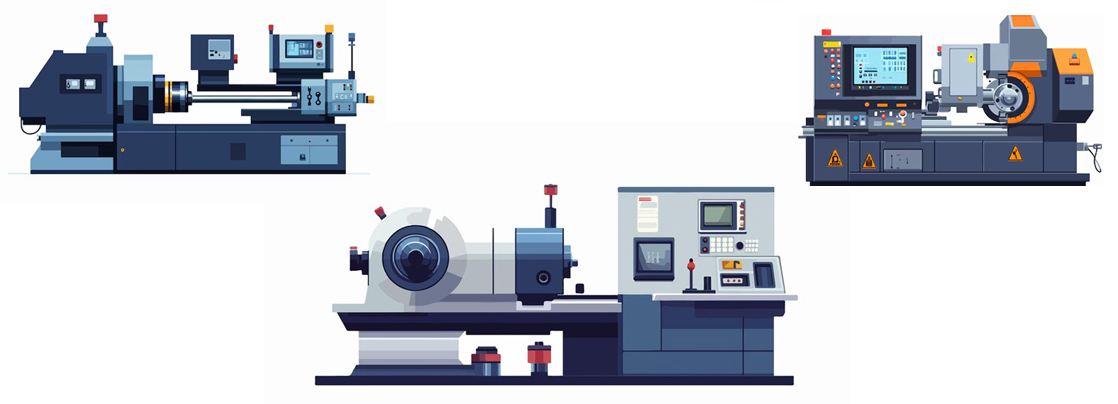

Machine Tools

Ever wondered how everyday products like cars, smartphones, or even kitchen appliances are made with such precision?

Machine tools are the heart of every workshop or factory. These powerful machines help create everything from small screws to car engines and aircraft parts. Without them, modern manufacturing would simply stop.

What Are Machine Tools?

Machine tools are devices used to cut or shape a workpiece by removing material. They operate with high precision, speed, and consistency, and are widely used in industries such as automotive, aerospace, electronics, and construction.

Machine Tools and Their Functions

Here are some important machine tools studied in this subject:

Lathe Machine

- Performs turning, taper turning, thread cutting, boring, and more.

- Types: Engine lathe, Capstan and Turret lathes, Automatic lathes

- Features include lathe attachments, tool-holding and work-holding devices

- Lathe operations: Facing, knurling, parting, grooving, etc.

- Specifications and classifications vary by size, power, and precision.

Shaper, Slotter, and Planer

- Shapers and slotters use reciprocating motion for cutting.

- The planer is suitable for large workpieces.

- All follow similar working principles but vary in application and size.

Drilling Machines

- Used to make round holes using twist drills.

- Operate based on rotary motion with axial feed.

- Include tool-holding devices and operations like reaming, tapping, and deep-hole drilling.

Milling Machines

- Use rotating cutters to remove material.

- Can perform face milling, end milling, slotting, and gear cutting.

- Classified into horizontal, vertical, and universal types.

- Specifications depend on spindle speed, power, and table size.

Grinding and Broaching Machines

- Grinding machines finish surfaces to fine tolerances using abrasives.

- Types: Cylindrical grinding, Surface grinding, Tool and cutter grinders

- Broaching machines are used for precision internal and external cutting.

- Includes surface, continuous, horizontal, and vertical types.

CNC Machines

- Computer-controlled machines for high-precision work.

- Common in modern industries for mass production.

Machining Parameters and Machinability

Cutting speed, feed rate, and depth of cut greatly affect surface finish, tool life, and power consumption. These are optimised depending on the material, tool type, and desired accuracy. The term machinability refers to how easily a material can be machined, influenced by its hardness, toughness, and thermal conductivity.

Why Are Machine Tools Important?

High Accuracy: Enables the production of parts with exact dimensions and minimal deviations

Increased Productivity: Speeds up manufacturing processes.

Consistency: Produces identical parts again and again.

Versatility: Can work with different materials and shapes.

Fun Fact

The first machine tool was invented in the late 18th century — the screw-cutting lathe! Since then, machine tools have come a long way and now use AI, robotics, and automation.

Conclusion

Machine tools are essential for shaping our modern world. From making engine parts to smartphone cases, they play a huge role in almost every product we use. Learning about them opens the door to the exciting world of manufacturing and engineering.