Topic: Industrial Automation: Shaping the Future of Manufacturing

In today’s fast-moving world, industries face the challenge of producing more, faster, and with better quality. Manual labour alone cannot meet these demands. That’s where industrial automation steps in. It uses machines, control systems, and technology to run processes with minimal human help. From simple conveyors to smart robots, automation has changed how factories work.

Real-World Examples

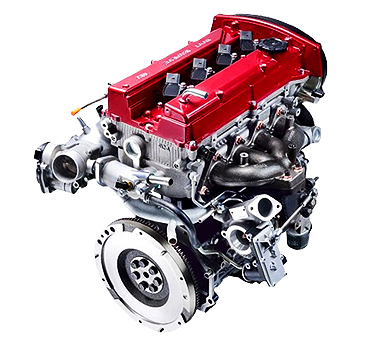

- Automotive: Robots on car assembly lines perform welding, painting, and part installation.

- Food Processing: Sensors and automated machines help in sorting, packaging, and quality checks.

- Textile: PLCs (Programmable Logic Controllers) control spinning and weaving machines for precise output.

- Pharmaceutical: Cleanroom robots handle drug packaging with no contamination.

Advantages of Industrial Automation

- Increased Productivity: Machines work faster than humans and without breaks.

- Better Quality: Automation ensures consistent, error-free results.

- Lower Costs: Though the initial setup is high, it reduces long-term labour costs.

- Safety: Automation reduces risks by handling dangerous tasks.

- Real-Time Monitoring: SCADA systems track production in real-time.

Disadvantages of Industrial Automation

- High Initial Investment: Setting up automation systems like robots and PLCs can be costly.

- Job Displacement: Some manual jobs may be replaced.

- Complex Maintenance: Skilled technicians are needed to maintain advanced systems.

- Cybersecurity Risks: Internet-connected machines can be targeted by hackers.

Key Technologies in Industrial Automation

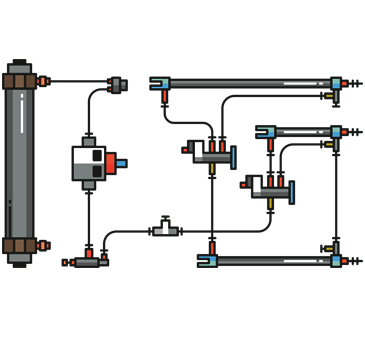

- PLCs: Act like the brain of a system, giving commands to machines.

- Sensors: Detect temperature, pressure, motion, etc., and send data to controllers.

- SCADA: Supervisory Control and Data Acquisition systems for real-time control and monitoring.

- Robotics: Perform tasks like assembly, inspection, and packaging.

- IoT (Internet of Things): Connects machines to the internet for smarter decision-making.

- AI and Machine Learning: Help machines learn patterns and improve operations.

Applications Across Industries

- Manufacturing: From smartphones to steel, automation increases output and accuracy.

- Oil and Gas: Monitors pipelines, storage tanks, and safety systems.

- Logistics: Automated warehousing and inventory tracking.

- Energy: Smart grids and power distribution.

- Agriculture: Automated irrigation and crop monitoring.

Emerging Trends and Future Scope

- Industry 4.0: A new phase where machines, data, and people work together using smart systems.

- Collaborative Robots (Cobots): Work safely alongside humans on shared tasks.

- Digital Twins: Virtual copies of physical systems for testing and planning.

- Predictive Maintenance: AI forecasts machine breakdowns before they happen.

- Edge Computing: Real-time data processing closer to the source instead of cloud delays.

Conclusion

Industrial automation is the backbone of modern industries. It boosts speed, efficiency, and safety. Though it brings challenges like high costs and the need for skilled labour, the benefits are far greater. With new technologies like IoT, robotics, and AI, the future of automation looks smarter, faster, and more connected than ever.

Whether you’re a factory owner, technician, or student, automation is a field worth watching!