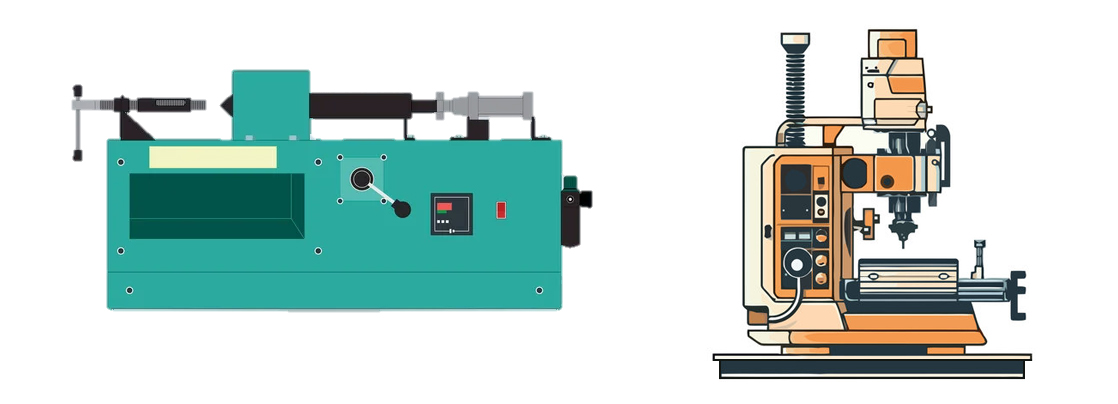

Fine Boring Machines

Fine boring machines are one of the important precision tools used in modern machining. One of the key features that make these machines special is their ability to produce high accuracy and fine surface finish. What exactly is fine boring, and where is it used? Let's explore this concept in detail.

What is Fine Boring?

Boring is a machining process that enlarges a drilled hole. Fine boring, as the name suggests, is a more precise version of this process. It is often used after rough boring or drilling to ensure perfect roundness, alignment, and smooth finish. Fine boring machines are designed to achieve this with the help of single or multiple spindles, controlled movements, and specialised cutting tools.

Main Parts and Functions

- Boring Spindle: The core component that rotates the cutting tool. It uses ball, roller, hydrostatic, or air bearings for smooth motion.

- Spindle Housing: Connects the spindle to the machine body and enables vertical feed.

- Cross Feed Lever: Mounted at the base, it allows longitudinal and transverse movement of the saddle and work table.

- Saddle: Holds the work table and moves in the longitudinal direction.

- Work Table: Holds the workpiece and moves at right angles to the spindle.

- Feed Mechanism: Either a cam or hydraulic cylinder gives axial feed.

- Control System: Many machines are numerically controlled with ball screw drives for precise saddle and table movements.

Types of Fine Boring Machines

- Horizontal Boring Machines

- Vertical Boring Machines

- Fine Boring Machines

- Jig Boring Machines

Advantages

- High accuracy and surface finish

- Ideal for complex, tight-tolerance components

- Automatic and NC controls ensure repeatability

- Capable of using multi-spindle heads for efficiency

Disadvantages

- High initial cost

- Requires skilled operators

- Not suitable for rough or heavy material removal

- Maintenance of high-precision parts can be costly

Applications of Fine Boring Machines

Fine boring machines are widely used in industries where accuracy is critical:

- Automotive Industry: For machining cylinder blocks and crankcases.

- Electrical Equipment: Used to bore motor casings.

- Hydraulic Systems: To accurately bore pump bodies and motor parts.

- Pipe Fitting Industry: For boring couplings and metal pipe ends to exact fits.

Conclusion

Fine boring machines offer a precise solution for finishing drilled holes in critical components. Their use in automotive, electrical, and hydraulic applications ensures optimal performance and reliability. Though they require a higher investment and expertise, their ability to deliver fine finishes and accurate dimensions makes them essential in precision machining tasks.