Title: CAD/CAM – The Digital Backbone of Modern Manufacturing

CAD CAM

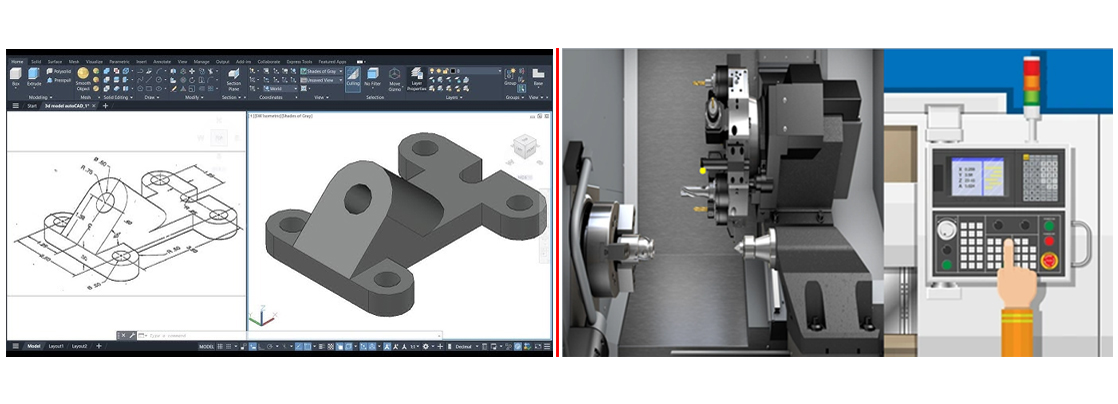

A small workshop once struggled to make custom machine parts by hand. Every curve was drawn on paper, and every mistake meant starting over. But when they switched to CAD/CAM software, things changed. They could now design parts digitally, simulate the toolpath, and send it straight to the CNC machine saving hours and reducing errors.

This shift is thanks to CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing), two powerful technologies that have transformed how products are designed and manufactured.

Let us now understand how CAD/CAM works and how it helps in real-world industries.

What is CAD and CAM?

CAD is used to create detailed 2D or 3D models of a part or product on a computer.

CAM takes that CAD model and generates the toolpaths and instructions to manufacture the part using a machine like a CNC mill or lathe.

Together, CAD and CAM enable a seamless design-to-production process—all within a digital environment.

Real-World Examples

In automotive design, engineers use CAD to model engine parts, while CAM sends those models to CNC machines for precise manufacturing. Dentists use CAD to design dental crowns, and CAM mills them out from ceramic blocks. Aerospace companies use CAD/CAM for lightweight structural parts with tight tolerances.

Software and Tools

- AutoCAD

- SolidWorks

- Fusion 360

- CATIA

- Mastercam

- NX Siemens

- PTC Creo

- CAMWorks

Advantages of CAD/CAM

- Accuracy: CAD drawings are dimensionally precise. CAM ensures exact machining.

- Speed: Reduces design-to-production time drastically.

- Repeatability: Parts can be easily replicated without manual errors.

- Complex Shapes: Allows the production of parts with curves, pockets, and contours that are hard to make by hand.

- Simulation: CAM software simulates tool movement, helping to detect problems before actual machining.

Disadvantages of CAD/CAM

- High Initial Cost: Software and training can be expensive for small businesses.

- Skilled Operators Needed: CAD/CAM software requires trained users to handle design and machine setup.

- Dependency on Computers: A system failure or file corruption can halt production.

Future Trends in CAD/CAM

- Cloud-Based Platforms: Enable designers and machinists to collaborate remotely, access models from anywhere, and use shared tools in real-time.

- AI-Driven Design: Use artificial intelligence to generate optimised designs and machining strategies automatically, reducing human effort and error.

- Additive Manufacturing Integration: Expand CAD/CAM capabilities to support 3D printing, complementing traditional subtractive methods.

- AR/VR Integration: Allow users to visualise, inspect, and interact with 3D models in immersive environments before production begins.

- Generative Design: Create multiple design iterations based on user-defined constraints like material, strength, weight, and cost.

- Sustainability: Focus on minimising material waste, improving energy efficiency, and enabling eco-friendly manufacturing processes.

Conclusion

CAD/CAM has bridged the gap between creativity and manufacturing. What starts as an idea on a screen becomes a real, functional product with accuracy and speed. Whether you're designing a turbine blade or a mobile case, CAD/CAM ensures precision, reduces waste and saves time.

In today’s fast-moving world, digital design and automated manufacturing are no longer a luxury, they're a necessity. So, the next time you hold a finely machined part, remember it was once just a line on a CAD screen.