Title: Hydraulics and Pneumatics – Power Behind Motion in Modern Machines

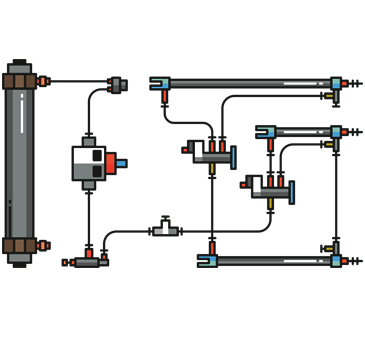

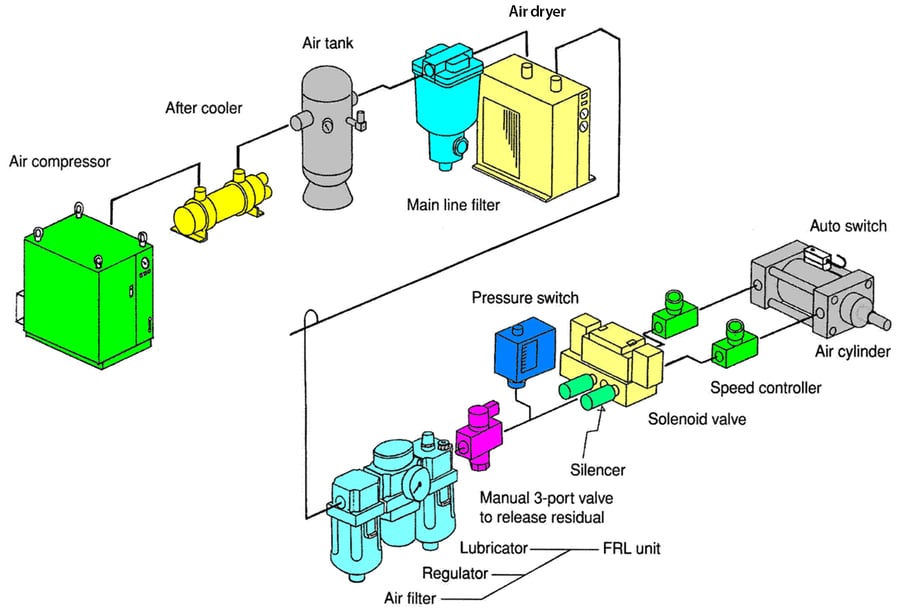

Pneumatic system

Every time a bulldozer lifts heavy soil or a robotic arm picks a delicate part in a factory, there's a hidden force at work—fluid power. Hydraulics and pneumatics are the core technologies that bring such machines to life. They may seem old-school, but these systems are evolving with smart automation, energy-efficient designs, and IoT integration.

So, what makes hydraulic and pneumatic systems so important even today? Let’s explore their working, real-life use, and where the future is heading.

What Are Hydraulics and Pneumatics?

- Hydraulics use liquid (usually oil) to transmit power. They are perfect for high-force and precise movement applications.

- Pneumatics use compressed air to generate motion. They are ideal for quick, light-duty operations.

Both fall under fluid power systems, and are widely used in industries like automotive, manufacturing, aerospace, and agriculture.

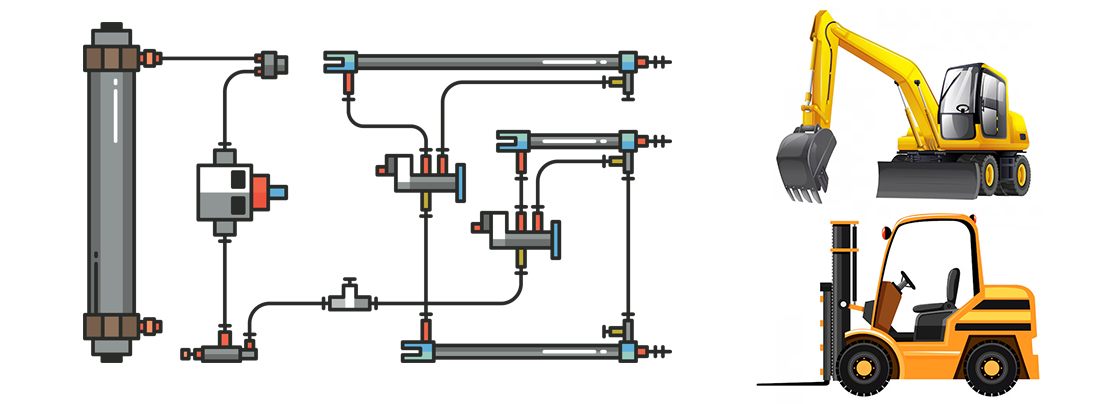

Examples of Hydraulic and Pneumatic Systems

- Hydraulics: Car braking systems, excavator arms, injection moulding machines.

- Pneumatics: Air-powered tools, packaging machines, conveyor systems, and robotic pick-and-place units.

These systems use components like cylinders, valves, actuators, and control units to manage flow and pressure.

Advantages

- High Power-to-Size Ratio: Especially in hydraulics—small systems deliver large force.

- Smooth and Precise Control: Excellent for applications needing variable force or position control.

- Fast and Clean Operation: Pneumatics are fast, lightweight, and easy to maintain.

- Safe for Hazardous Areas: Pneumatic systems don’t involve heat or sparks, ideal for explosive environments.

Disadvantages

- Energy Losses: Leakage and friction can reduce efficiency.

- Noise and Vibration: Pneumatics are generally noisier.

- Maintenance: Hydraulic fluid needs regular checks for contamination and level.

- Lower Precision (Pneumatics): Harder to control speed or force with high accuracy.

Application Areas

- Manufacturing Automation: Pneumatic pickers and hydraulic presses.

- Construction Equipment: Hydraulic lifts, loaders, and diggers.

- Aerospace & Defence: Aircraft control systems and weapon loaders.

- Food & Pharma: Pneumatic actuators for cleanroom operations.

- Material Handling: Forklifts, conveyors, and clamping systems.

Emerging Trends

Hydraulics and pneumatics are rapidly evolving with the integration of advanced technologies. One major trend is the rise of IoT-enabled components, where smart sensors continuously monitor fluid levels, system pressure, and component wear, enabling real-time diagnostics. Another notable trend is the development of electro-hydraulic and electro-pneumatic systems, which merge the precision of electronics with the force of fluid power. Additionally, AI-powered predictive maintenance is becoming popular, allowing operators to identify potential issues before breakdowns occur, thus enhancing reliability and reducing downtime.

Future Outlook

The future of hydraulics and pneumatics is aligned with the goals of Industry 4.0, focusing on automation, connectivity, and efficiency. Systems will be fully integrated with digital control platforms, offering seamless communication between machines. Smart actuators and intelligent valves will allow greater control and flexibility. There will be a stronger emphasis on sustainable designs, with a shift toward using biodegradable fluids and low-energy components.

Conclusion

Hydraulics and pneumatics may be traditional technologies, but they are far from outdated. With the rise of automation and smart manufacturing, these systems are becoming smarter, cleaner, and more connected than ever.

Whether you're lifting tonnes of earth or sorting packets at lightning speed, fluid power remains the invisible force that keeps machines moving.